When I see internal walls start to go up, albeit without plaster, I dare to imagine that the end is in sight. It’s definitely starting to look more like a house.

We continue to move slowly towards completion with plaster boarding, wiring and ducting all now happening simultaneously.

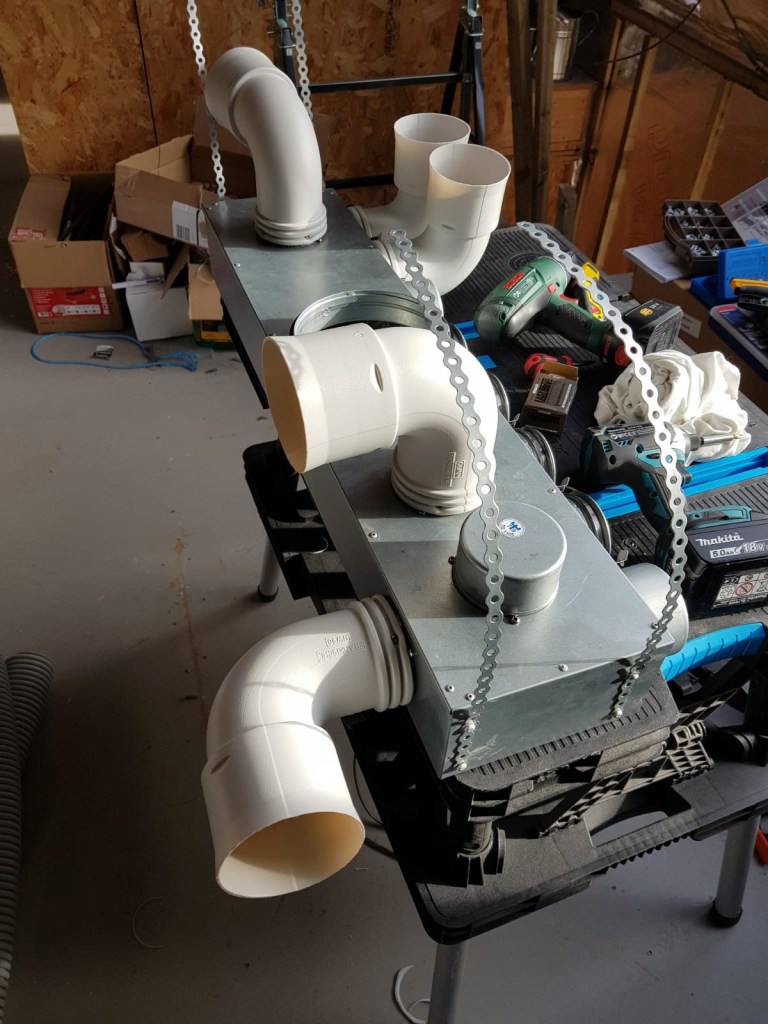

Husband has been fitting the ducting to take the mechanical ventilation pipes (the MVHR system) around the house. These pipes all come together in an interim pit stop over the appliance wall in the kitchen before snaking their way across to the plant room to be connected to their master.

To say that our architects were optimists and highly impractical would be an understatement. Watching husband try to adapt the manifold to fit the pipes into the area allocated to it on the plans was painful.

Speaking to other Hebhome builders it seems that others give up or don’t even try, and instead site the manifold in a cupboard upstairs, but husband was not easily deterred, and some days later Frankenfold was born…

A child born of ingenuity and galvanised steel drainpipe to cap off the unused bits, the manifold was adapted to fit the space. Not pretty, but perfectly functional. Our very own Frankenstein creation.

It’s now all in position and connected, looking purposeful.

I’m very proud.